PROFILE GRINDING WHEELS

CHARACTERISTICS AND USAGE OF OUR WHEELS

Profile grinding is an efficient method of machining various profiles in workpieces. This method helps achieve very high surface quality of the machined workpiece.

Multiple types of grinding methods can be considered as Profile Grinding:

- Plunge Grinding – profile can be ground into a workpiece by plunging into the machined material.

- Free Grinding – of various shapes and profiles into workpieces.

- Contour Grinding – usually done by grinding outer diameters of the machined workpieces.

Machined workpieces:

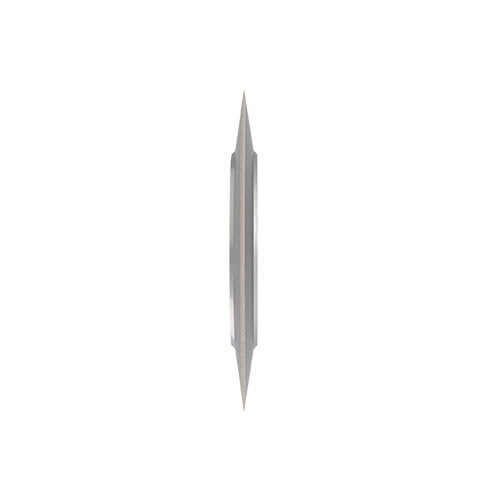

With these wheels you can mainly produce End Mills from tungsten carbide, HSS and hardened steels with 52 HRC, but also other products.

Available products and services

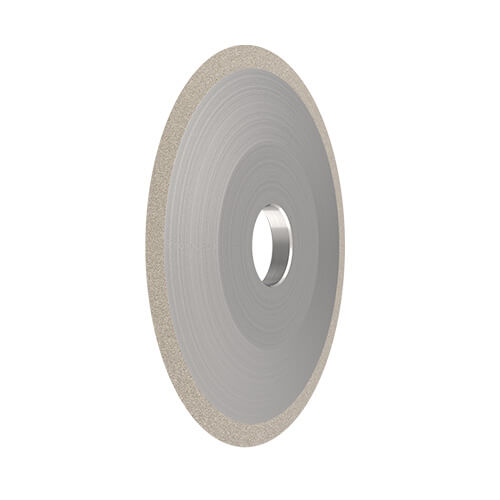

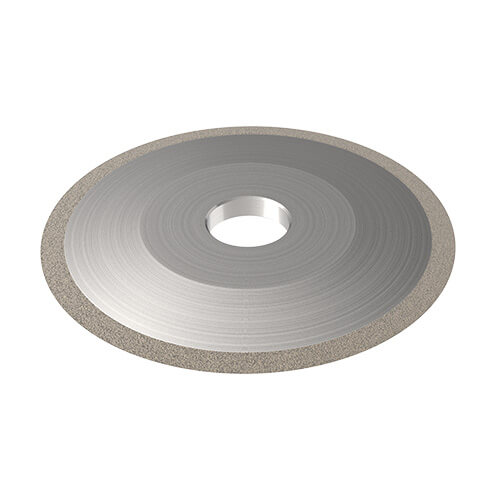

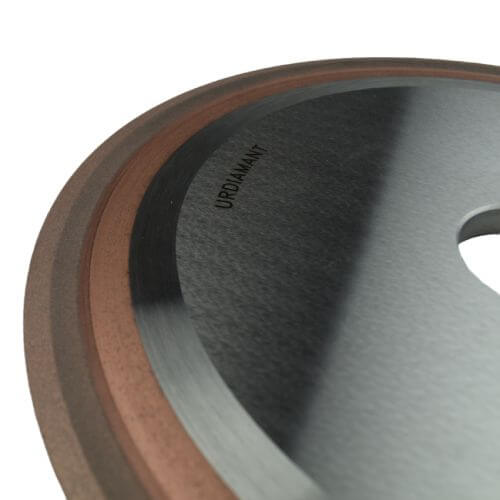

Wheel types and dimensions:

- Outer wheel´s diameter: 50 – 200 mm

- Wheel types: 1E1; 14E1; 3E1

- Grit sizes: D39; D46; D54; D64; D76 a B107

- Bond types: We will help you select the right metal (or other) bond for your application. Contact us for consultancy.

For grinding machines:

CNC PFS 30 PeTeWe, AMADA, MÄGERLE, OKAMOTO, Reinecker WZ 70, 60 , 40, WAIDA, atd.

Grinding conditions for diamond wheels:

- Peripheral velocity of the grinding wheel: 22-25 m/s

- Infeed (depth of cut): 0,05 – 0,3 mm

- Feedrate: 60 – 120 mm/min

Re-profiling service:

Upon consultancy, we can renovate (true and dress) your profile grinding wheels. Send us your inquiry!

SEE EXAMPLES OF OUR PRODUCTS

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653