Grinding Wheels for Broaches

Characteristics and usage of our wheels

Broaching is a machining process that utilizes toothed tool, called broach to remove material from the workpiece. Broaching is used to machine circular & non-circular holes as well as outer profiles various workpieces. Broaching can be dividided into internal and surface type, depending on whether the broach removes material from within, or from the outside of the workpiece.

A broach is effectively a collection of single-point cutting tools arrayed in sequence, cutting one after the other – these cutting tools are called “teeth”. A broach consists of 4 parts: fixing, guiding, cutting and calibrating.

Cutting part of a broach can be equiped with chip breakers (=notches in the teeth of a broach) in order to allow better creation and breakage of chip. Teeth of the calibrating part are not equiped with chip breakers and are of the same height and can be re-ground. Lastly, a broach can be equiped with polishing teeth that are higher than calibrating teeth by 0,001 to 0,005 mm to maximaze the surface quality of a workpiece.

Maximal length of a broach is affected by the setup of the broaching machine. Broach would be divided into multiple parts if the total length of broaching is too big. The guiding part helps to center the tool in a machined hole (in case of internal broaching).

Available products and services

We produce all standard types of grinding wheels for production or re-sharpening of broaches. Furthermore, we also provide individual solutions based on customers’ requests. Send us your inquiry.

Ground material: HSS (High Speed Steel); PM HSS (Powder Metallurgy High Speed Steel; PM HSS is more suitable for machining very hard and more diffultly machineable materials like e.g. titanium); tungsten carbide (for rare purposes of machining cast iron).

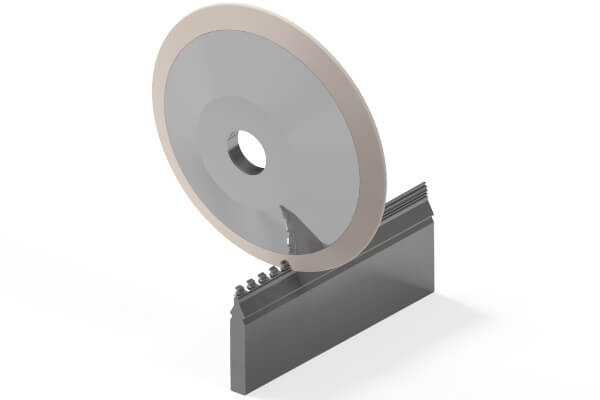

FEPA shapes of the grinding wheels: 4BT9; 14F1

Suitable for grinding machines:

Schneeberger Corvus, AMADA, Arthur Klink, Mägerle, Schütte, ABA and other

grinding conditions

EXAMPLES OF OUR GRINDING WHEELS

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653