DIAMOND POLISHING & LAPPING PASTES / COMPOUNDS

Features and usage of diamond pastes / compounds

Diamond pastes & compounds have better cooling and lubracting features compared to standard grinding compounds and pastes. Thanks to this fact, diamond pastes & compounds allows increase the lapping / polishing speed by 2-5 times and thus increase quality of the machined surface.

We recommend using diamond paste for lapping and polishing of tools and parts from tungsten carbide, technical ceramics, quartz and other very hard materials.

Diamond pastes & compounds are used in engineering industry for finishing operations on e.g. industrial tools, sintering molds, pressing molds, nozzles, drawing swages, etc. They are used for machining parts with very high tolerances, like parts of hydraulic and fuel systems, pressing molds for plastics, or for polishing of stone and gemstones.

Diamond grit sizes of pastes & surface quality

If you cannot see the full table, scroll right

| Ra | GRIT SIZE | COLOR CODING | ||||

| 0,020 – 0,040 | 0,032 – 0,063 | 0,063 – 0,100 | 0,100 – 0,160 | FEPA | Micron distribution | |

| D0,7 | 1/0 µm | LIGHT YELLOW | ||||

| D2 | 3/2 µm | YELLOW | ||||

| D3 | 5/3 µm | LIGHT GREEN | ||||

| D6 | 7/5 µm | GREEN | ||||

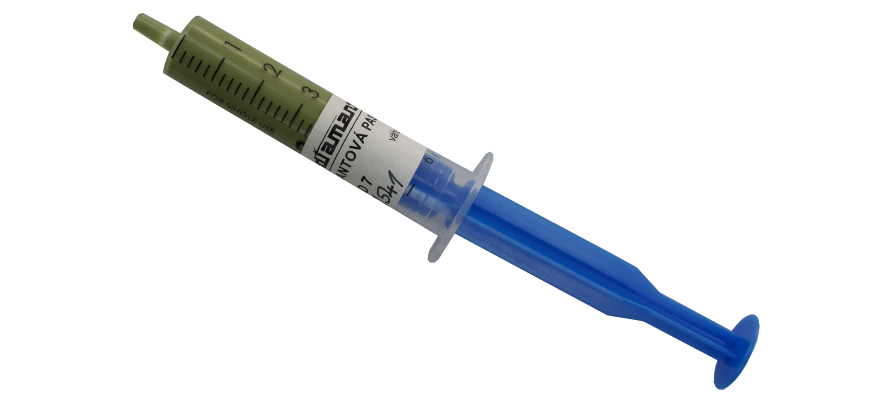

| D7 | 10/7 µm | DARK GREEN | ||||

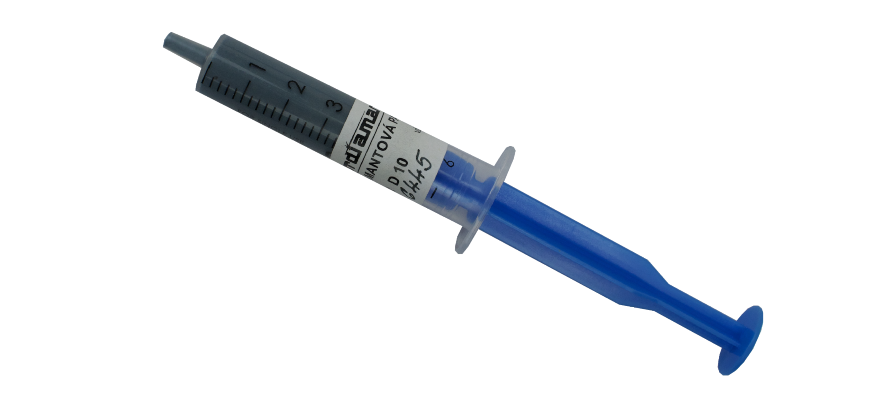

| D10 | 14/10 µm | LIGHT BLUE | ||||

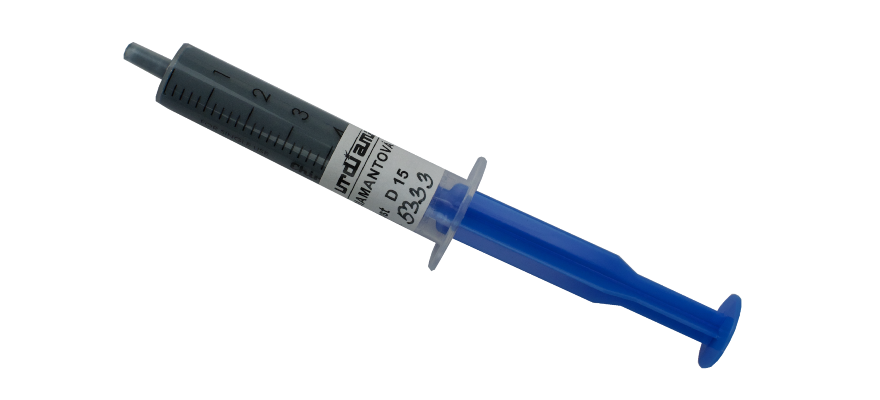

| D15 | 20/14 µm | BLUE | ||||

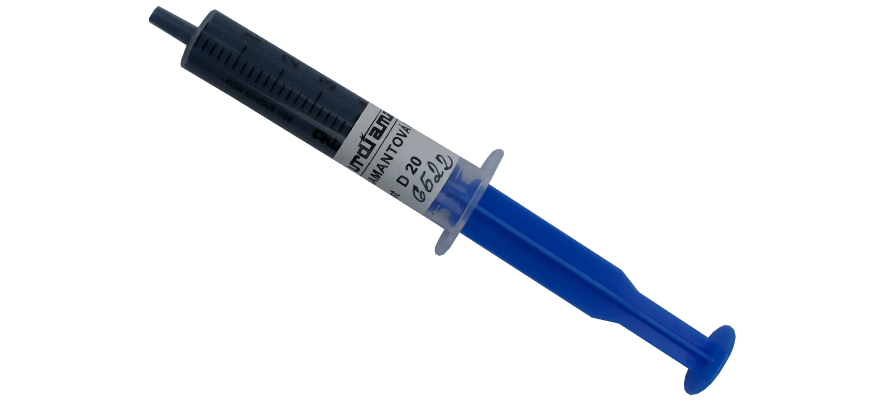

| D20 | 28/20 µm | DARK BLUE | ||||

| D27 | 40/28 µm | RED | ||||

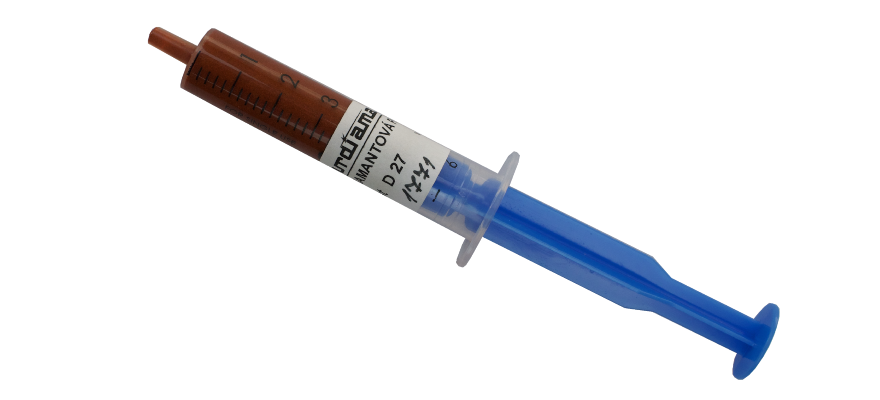

Labeling and packaging

Our pastes are supplied in plastic containers (form of a syringe) of different sizes and can be ordered by piece.

Available sizes of containers: 5g / 10g / 20g / 50g

Safery data sheet

D0,7 = D1/0

D2 = D3/2

D3 = D5/3

D6 = D7/5

D7 = D10/7

D10 = D14/10

D15 = D20/14

D20 = D28/20

D27 = D40/28

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653