CENTERLESS GRINDING WHEELS

CHARACTERISTICS AND USAGE OF OUR WHEELS

Centerless grinding is an effective method of machining vast amount of workpieces down to a required diameter.

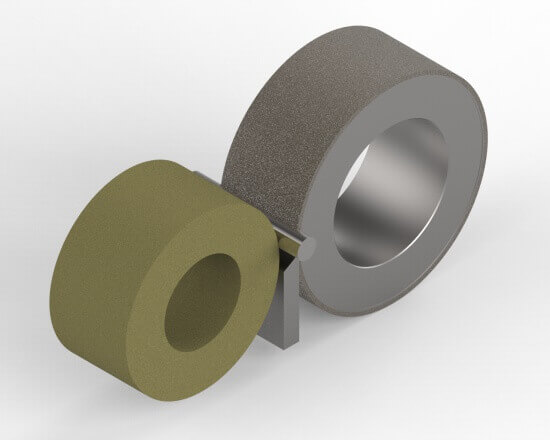

By Centerless Gringing, we understand a grinding method, where workpiece is not fixed within a tool holder during the grinding process, but is placed between two wheels. One of which is regulating and the other is a grinding wheel.

The wheels turn in an opposite direction and the turning speed affects the material removal rate. The grinding wheel is made with diamond, or CBN, whilst the regulating wheel is usually made out of rubber to help fix the ground workpiece.

Machined Materials

- Technical Ceramics

- Hardened Steels and Powder Steels

- Tungsten Carbide

Available products and services

To see the rest of the table, scroll right

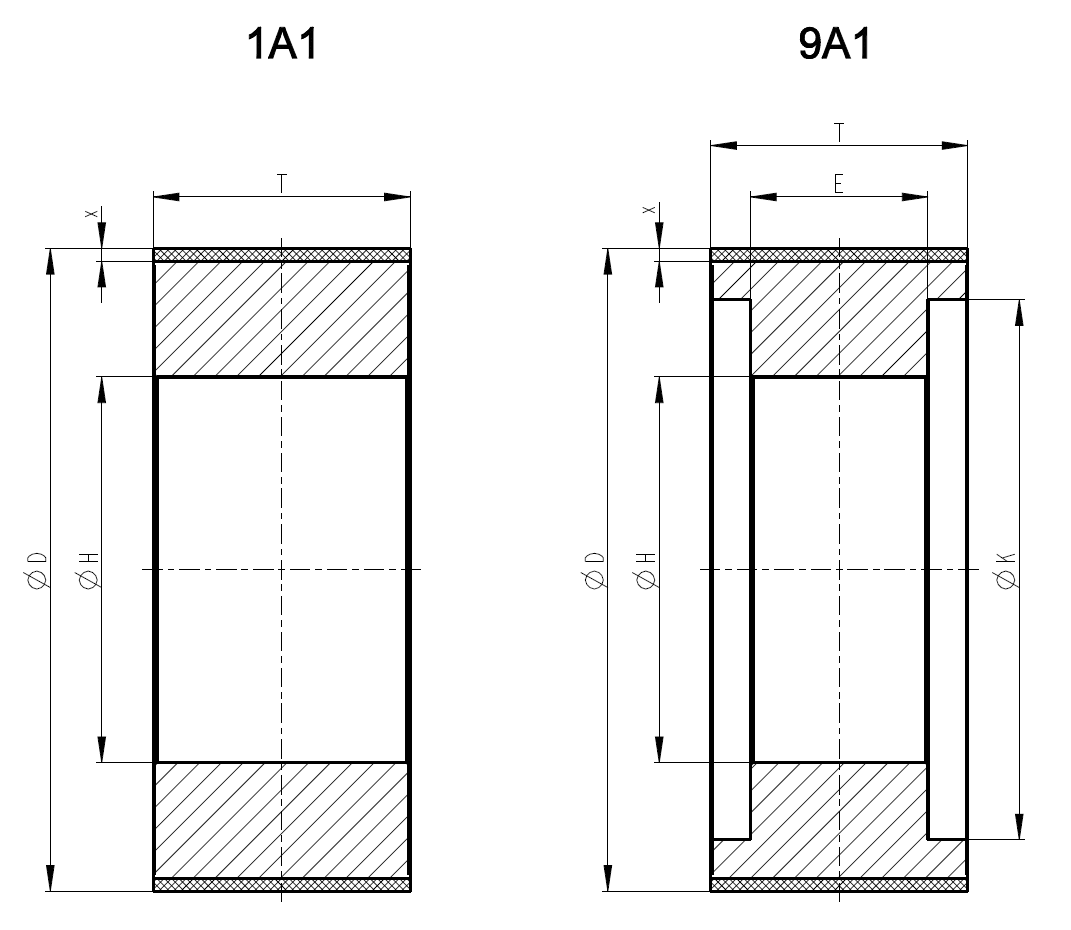

| Bond | ØD | T | x | Type and Dimensions |

| Metall | 250 | 60 | 3 |  |

| 80 | 3 | |||

| 300 | 80 | 3 | ||

| 100 | 3 | |||

| 350 | 100 | 4 | ||

| 150 | 4 | |||

| 200 | 4 | |||

| Resinous | 250 | 60 | 5 | |

| 80 | 5 | |||

| 300 | 80 | 5 | ||

| 100 | 5 | |||

| 350 | 100 | 5 | ||

| 150 | 5 |

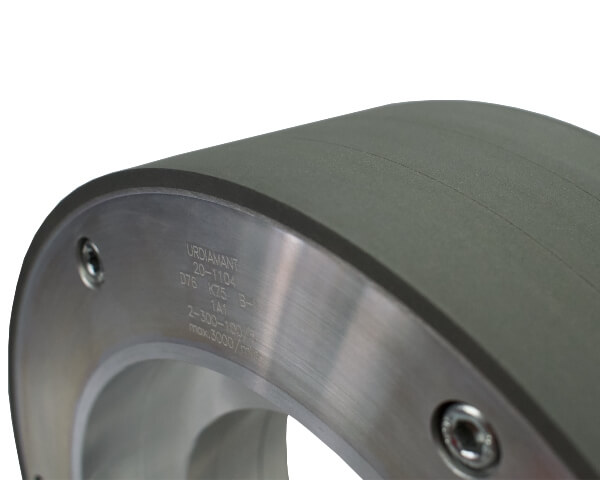

Grinding Layer: We can customize the grit size of the grinding wheel´s active layer(s) to meet the customer´s requirement of the workpieces surface quality / roughness.

Offered services:

- As a service, we can true and dress the wheels for our customers.

- To achieve the best possible result, we true and dress the wheels upon customer´s flange.

- Contact us for more information.

Applicable grinding machines

See examples of our products

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653